How the 11 series Riata® Rake arena harrow works

The features of the 11 Series Riata Rake arena harrow provide a total method for safety and precision beginning with its compact, “close to tractor” frame. This compact frame allows the rake to make tight turns with little or no side-to-side sliding and/or gouging. The frame extends the overall tractor length by only 4 feet from the 3-point hitch.

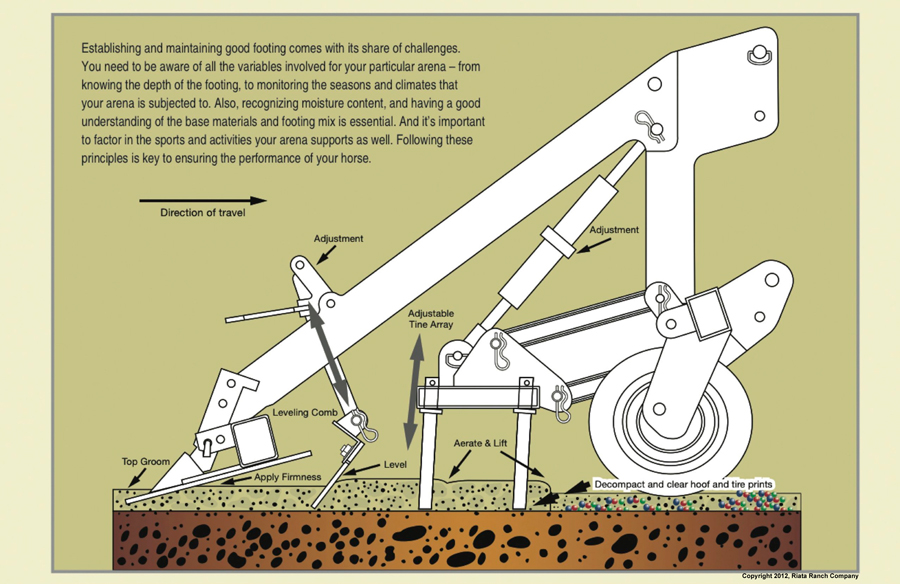

Phase One – The weight of the 11 Series Riata Rake arena harrow provides optimal holding depth for the tine bar, which is the first part of the rake that engages with the arena footing. The tine bar is designed to aerate and condition all types of footing composites with varying moisture content to allow flow and de-compaction down to the compacted base of the arena. The tine spacing (2.75″ apart) ensures that hoof and tractor tire compaction is removed in a single pass. The tines are made of high carbon alloy steel, which are heat treated for long wear, and are adjustable for precise footing depth from 1″ to 6″ with our ratchet jack. Additionally, the tines are angled (or swept back) to eliminate chatter, making Riata Rake a smooth and stable tool to operate. Adjustable-gauge tires are a standard feature on the Riata Rake arena harrows and provide depth control and stability, which allows any low areas to be filled on the compacted base.

Phase Two – The 11 Series Riata Rake is the only arena drag with our patent-pending, auto-leveling comb, which, in combination with the tine bar, redistributes and levels the arena footing with every pass to ensure that your arena surface is level from the base to the top of footing. Every unit is equipped to accept an optional hydraulic control for moving footing material in high use equestrian arenas.

Phase Three – The final touches on your arena are completed with our compaction plate and rear-finishing comb. The finish is always beautiful, but more importantly, it is consistent in density from the base to the top of footing. The weight and angle of the finishing comb produces a constant PSI across the entire arena, which provides a feel that professionals say is “just right”.

Maintenance Phase – Periodically, every arena may need to be ripped to bring back the base after heavy use and bad weather. The 11 Series Riata Rake arena harrows are equipped with a unique method of ripping the arena with precision that can only be found with excellent design and engineering. The rippers are located just before the rear-finishing comb. The rear comb serves as the gauge for the rippers and allows accurate, dependable ripper depth control, consistent throughout the arena.

For the land that I love™ Riata has a reputation of making its products with the highest quality materials, welding techniques, and finishes. Every Riata Rake arena harrow is powder coated to ensure that it looks as good as it performs, even after years of every day use. Riata guarantees its products for one full year and provides a complete line of arena harrows for any arena, any tractor, and/or any ATV, UTV, or SxS vehicle.