Dr. Hilary M. Clayton, BVMS, PhD, Diplomate ACVSMR, MRCVS

McPhail Dressage Chair in Equine Sports Medicine

Department of Large Animal Clinical Sciences

College of Veterinary Medicine, Michigan State University East Lansing, MI 48824-1314

Different types of footing have advantages and disadvantages with regard to performance and soundness of the equine athlete. The ideal footing for a specific arena or track depends on the type of sport being performed, the local climate, and the location (indoors or outdoors). It is easier to choose a suitable surface for a single sport in an indoor arena than it is to cater to the needs of several different sports in an outdoor arena, where the unpredictable effects of weather play a role. The capital investment and the practicalities of maintaining the surface on a day-to-day basis are also important considerations in the long-term cost and, as a result, the end product is often a compromise between the ideal and the practical/affordable. When choosing a work surface for performance horses, two important properties are the impact resistance and the shear resistance of the surface material.

Impact Resistance

The hoof is moving forward and downward when it contacts the ground. It is rapidly decelerated and brought to rest within about 20 milliseconds (1/20 second) after ground contact. This rapid deceleration causes concussion, which is potentially damaging, especially to the bones and joints. Impact resistance describes the ability of the footing to absorb concussion when the hoof strikes the ground. Hard surfaces, such as blacktop, have high impact resistance and are not effective in absorbing concussion during the impact phase. Surfaces with a lower impact resistance, such as wood and rubber chips of synthetic additives, absorb concussion as they are compressed during impact. This results in lower concussion on the limbs. The depth of the hoof print is an indicator of the impact resistance of a surface: the deeper the hoof print, the lower the impact resistance and concussion that is transmitted to the horse’s bones and joints. High impact resistance is associated with a greater risk of concussive injuries such as fractures and degenerative joint disease (osteoarthritis).

Shear Resistance

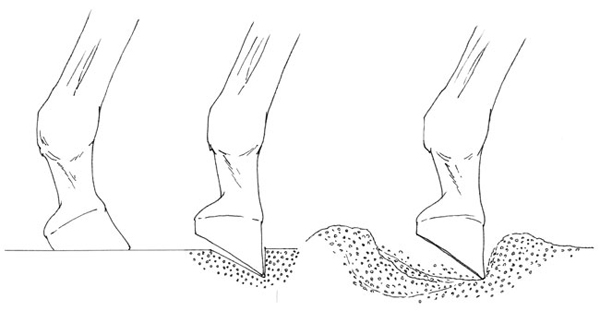

Figure 1. Diagram of the interaction of the hoof with surfaces that have different impact and shear resistance. Left: a hard surface with high shear resistance does not allow the toe to dig in during push off. Center: a surface with moderate impact and shear resistance allows the doe to dig but then offers resistance as the hoof pushes off. Right: a soft surface with low shear resistance gives way and does not offer sufficient resistance as the hoof pushes off.

Shear resistance describes the ease with which the footing is displaced by a shearing (rotational) force. When the leg is pushing against the ground to generate propulsion, the toe tends to rotate into the surface. The shear resistance of the footing should be low enough to allow the toe to dig in as the hoof pushes against it (Figure 1), which has the dual benefits of reducing tension in the distal check ligament and reducing pressure of the deep digital flexor tendon on the navicular region. The shear resistance can, however, be too low. When this is the case, the ground does not offer sufficient resistance to the hoof pushing against it. Instead, the surface gives way during push off and the muscles have to work harder to generate propulsion (think about how it feels to run on deep, dry sand on the beach). As a consequence of having to work harder, the muscles become fatigued more quickly and this predisposes the horse’s ligaments and tendons to injuries. Surfaces with a very low shear resistance, such as deep, dry sand, are very tiring for the horse and, if used in excess, may lead to ligament and tendon injuries.

Hard surfaces (concrete, blacktop) have high shear resistance, which does not allow the toe to dig in. These surfaces not only exacerbate problems associated with concussive injuries, but they also tend to increase lameness in horses with palmar heel pain or navicular syndrome. Sometimes the shear resistance of a surface can be changed by management practices. For example, the addition of water to deep, dry sand increases its shear resistance – this explains the difference between running along the beach at the edge of the water versus running in the sand dunes.

Footing Materials

Hard surfaces, such as concrete, asphalt, and hard-packed soil, have high impact resistance and high shear resistance. When a horse works on these surfaces, the legs are subjected to considerable concussion at impact and, since the toe is unable to penetrate the surface during breakover, there are high loads on the navicular region in the terminal stance. These effects are used as an advantage by veterinarians to assist in lameness diagnosis because horses with bone and joint injuries will show more lameness when examined on a hard surface.

Sand is the most commonly used footing due to its availability and cost effectiveness. However, sand varies widely in its physical properties and some types of sand make much better footing than others. The relevant considerations are size, shape and hardness. The size of the sand grains affects dustiness, compaction, and water retention. Ideally, arena sand should be predominantly medium coarse (0.25-0.5 mm) and coarse grains (0.5-1.0 mm). Coarse sand drains more easily than fine sand in an outdoor arena. On the other hand, sand with a lot of very fine particles is dusty when dry and compacts when it gets wet and then dries out. Angular sand grains are preferable to round grains because they lock together, forming a more stable surface that requires less maintenance. Round grains of sand tend to roll over each other like ball bearings, so the footing is less stable and more prone to shifting. Hard sand is more durable, whereas soft sand tends to break down and turn to dust after relatively little use. Hardness can be tested by placing a few grains of the sand on a hard surface and compressing them with a teaspoon. If the grains crush easily, the sand is soft.

Sand has lower impact resistance than hard soil, combined with a low shear resistance, which allows the toe of the hoof to penetrate deeply. Deep, dry sand tends to give way during push off, resulting in loss of traction, making it very tiring for the horse to work on. Trainers need to be careful to reduce the amount of exercise when changing to a deeper sand footing – otherwise there is a risk of overuse injuries to the soft tissues. When sand is wet, the grains adhere to each other due to surface tension, making it more stable and less tiring for the horse to work on than dry sand. Regular watering is recommended for deep sand arenas.

Amendments, such as rubber, wood chips, or fibers, may be added to sand to improve its properties as a riding surface. Fibers or shredded materials stabilize the sand grains. Rubber and wood products give more resilience and reduce packing. Wood products also help to hold moisture in the surface.

Bonding agents, such as water and polymers, are added to arena surfaces primarily to reduce dust. Hygroscopic agents, such as magnesium chloride, take up and retain water, so their addition to a surface reduces the frequency of watering.

Arena surfacing is big business and there are many different types and formulations for footing. Some products are based on polymer-coated sand that eliminates dust, while others have a composition that gives a soft, bouncy ride. These are usually relatively expensive and all have specific recommendations for maintenance.

Footing Materials

Hard surfaces, such as concrete, asphalt, and hard-packed soil, have high impact resistance and high shear resistance. When a horse works on these surfaces, the legs are subjected to considerable concussion at impact and, since the toe is unable to penetrate the surface during breakover, there are high loads on the navicular region in the terminal stance. These effects are used as an advantage by veterinarians to assist in lameness diagnosis because horses with bone and joint injuries will show more lameness when examined on a hard surface.

Sand is the most commonly used footing due to its availability and cost effectiveness. However, sand varies widely in its physical properties and some types of sand make much better footing than others. The relevant considerations are size, shape and hardness. The size of the sand grains affects dustiness, compaction, and water retention. Ideally, arena sand should be predominantly medium coarse (0.25-0.5 mm) and coarse grains (0.5-1.0 mm). Coarse sand drains more easily than fine sand in an outdoor arena. On the other hand, sand with a lot of very fine particles is dusty when dry and compacts when it gets wet and then dries out. Angular sand grains are preferable to round grains because they lock together, forming a more stable surface that requires less maintenance. Round grains of sand tend to roll over each other like ball bearings, so the footing is less stable and more prone to shifting. Hard sand is more durable, whereas soft sand tends to break down and turn to dust after relatively little use. Hardness can be tested by placing a few grains of the sand on a hard surface and compressing them with a teaspoon. If the grains crush easily, the sand is soft.

Sand has lower impact resistance than hard soil, combined with a low shear resistance, which allows the toe of the hoof to penetrate deeply. Deep, dry sand tends to give way during push off, resulting in loss of traction, making it very tiring for the horse to work on. Trainers need to be careful to reduce the amount of exercise when changing to a deeper sand footing – otherwise there is a risk of overuse injuries to the soft tissues. When sand is wet, the grains adhere to each other due to surface tension, making it more stable and less tiring for the horse to work on than dry sand. Regular watering is recommended for deep sand arenas.

Amendments, such as rubber, wood chips, or fibers, may be added to sand to improve its properties as a riding surface. Fibers or shredded materials stabilize the sand grains. Rubber and wood products give more resilience and reduce packing. Wood products also help to hold moisture in the surface.

Bonding agents, such as water and polymers, are added to arena surfaces primarily to reduce dust. Hygroscopic agents, such as magnesium chloride, take up and retain water, so their addition to a surface reduces the frequency of watering.

Arena surfacing is big business and there are many different types and formulations for footing. Some products are based on polymer-coated sand that eliminates dust, while others have a composition that gives a soft, bouncy ride. These are usually relatively expensive and all have specific recommendations for maintenance.

Footing Materials

Hard surfaces, such as concrete, asphalt, and hard-packed soil, have high impact resistance and high shear resistance. When a horse works on these surfaces, the legs are subjected to considerable concussion at impact and, since the toe is unable to penetrate the surface during breakover, there are high loads on the navicular region in the terminal stance. These effects are used as an advantage by veterinarians to assist in lameness diagnosis because horses with bone and joint injuries will show more lameness when examined on a hard surface.

Sand is the most commonly used footing due to its availability and cost effectiveness. However, sand varies widely in its physical properties and some types of sand make much better footing than others. The relevant considerations are size, shape and hardness. The size of the sand grains affects dustiness, compaction, and water retention. Ideally, arena sand should be predominantly medium coarse (0.25-0.5 mm) and coarse grains (0.5-1.0 mm). Coarse sand drains more easily than fine sand in an outdoor arena. On the other hand, sand with a lot of very fine particles is dusty when dry and compacts when it gets wet and then dries out. Angular sand grains are preferable to round grains because they lock together, forming a more stable surface that requires less maintenance. Round grains of sand tend to roll over each other like ball bearings, so the footing is less stable and more prone to shifting. Hard sand is more durable, whereas soft sand tends to break down and turn to dust after relatively little use. Hardness can be tested by placing a few grains of the sand on a hard surface and compressing them with a teaspoon. If the grains crush easily, the sand is soft.

Sand has lower impact resistance than hard soil, combined with a low shear resistance, which allows the toe of the hoof to penetrate deeply. Deep, dry sand tends to give way during push off, resulting in loss of traction, making it very tiring for the horse to work on. Trainers need to be careful to reduce the amount of exercise when changing to a deeper sand footing – otherwise there is a risk of overuse injuries to the soft tissues. When sand is wet, the grains adhere to each other due to surface tension, making it more stable and less tiring for the horse to work on than dry sand. Regular watering is recommended for deep sand arenas.

Amendments, such as rubber, wood chips, or fibers, may be added to sand to improve its properties as a riding surface. Fibers or shredded materials stabilize the sand grains. Rubber and wood products give more resilience and reduce packing. Wood products also help to hold moisture in the surface.

Bonding agents, such as water and polymers, are added to arena surfaces primarily to reduce dust. Hygroscopic agents, such as magnesium chloride, take up and retain water, so their addition to a surface reduces the frequency of watering.

Arena surfacing is big business and there are many different types and formulations for footing. Some products are based on polymer-coated sand that eliminates dust, while others have a composition that gives a soft, bouncy ride. These are usually relatively expensive and all have specific recommendations for maintenance.